Chemical Industry and Metal stamping parts

The core characteristics of stamping parts in the chemical industry are: expensive materials (often using titanium, nickel based alloys, 316L stainless steel) and complex structures (in order to increase contact area).

The following are the specific roles and application scenarios of metal stamping parts in the chemical industry:

1. Tower Internally - the core of chemical production

In distillation towers, absorption towers, and washing towers, sufficient contact between gas-liquid phases is required to achieve material separation. Most of the core components inside these towers are stamped parts.

Trays & Caps:

Bubble Caps: This is an inverted bowl shaped structure with grooves on the edges. It is a typical stretching and punching stamping part. Its function is to disperse the rising gas into small bubbles through the tooth groove, pass through the liquid layer, and increase the gas-liquid contact area.

Valves: movable metal plates installed on tray holes, lifted by airflow.

Structured Packing:

Function: Replace the tray and provide a huge surface area.

Craftsmanship: This type of filler is made of extremely thin metal plates (stainless steel or aluminum), which are then Corrugged, punched, and assembled in layers. The corrugated structure formed by stamping determines the separation efficiency.

2. Plate Heat Exchanges - The Key to Energy Efficiency

Chemical production is accompanied by a large number of heating and cooling processes. Plate heat exchangers are widely used due to their high efficiency and small footprint.

Heat Transfer Plates:

Function: Two fluids flow on both sides of the plate for heat exchange.

Craftsmanship: This is one of the most technologically advanced stamping parts in the chemical industry. Use a 10000 ton hydraulic press to press thin metal plates (such as titanium plates and Hastelloy plates) into complex herringbone ripples.

Key point: The punched ripples not only increase strength, but also generate strong turbulence in the fluid, greatly improving heat transfer efficiency.

3. Filtration & Separation

Chemical raw materials and products often require filtering impurities.

Perforated Metal/Sieves:

Function: Support filter media or directly perform coarse filtration.

Process: CNC punching machines punch thousands of tiny holes (round holes, square holes, long waist holes) on metal plates.

Filter end cap:

The metal covers at both ends of industrial filter cartridges are usually stamped and used to secure filter paper or mesh.

4. Piping & Sealing

Chemical pipelines are like blood vessels in the human body, and their connections must be absolutely sealed to prevent the leakage of toxic and harmful substances.

Spiral Wound Gaskets:

Function: Sealing element at flange connection.

Process: Its main body is a V-shaped or W-shaped metal strip (stamped), which is alternately wrapped with graphite strips. The elastic rebound of metal strips is the key to sealing.

Blind Flanges:

For low-pressure pipelines, thinner blind plates can be cut and formed by stamping, which is cheaper than forging blind plates.

Pipe clamps and brackets:

Fix complex chemical pipeline corridors to prevent pipeline vibration.

5. Safety Devices - Ensuring Life

Chemical equipment often operates under high pressure, and once overpressure occurs, it may explode.

Rupture Disks:

Function: When the pressure exceeds the limit, this metal plate will "actively rupture" before the equipment to release pressure and protect the equipment from explosion.

Craftsmanship: This is an extremely precise stamped component. It is usually made of nickel, Monel alloy or stainless steel, and is prefabricated with arches or scratches through precision molds. Its thickness and scratch depth must be precisely controlled to ensure that it fractures instantly at an accurate pressure value (such as 1.05MPa).

6. Tank Heads

Although the heads of large storage tanks are spun, the heads of small and medium-sized chemical containers are often stamped.

Dish shaped/elliptical head:

Function: Close both ends of the pressure vessel.

Process: Use a large hydraulic press for deep stretching. Stamped heads bear more uniform force and are more resistant to high pressure than welded heads.

Why does the chemical industry rely on stamped parts?

Special material processing capability:

The chemical industry extensively uses expensive and difficult to process materials such as Titanium, Nickel, Hastelloy to prevent corrosion. Cutting these materials is very difficult and wasteful (materials are extremely expensive). Stamping technology belongs to "less cutting" processing, with high material utilization rate, which is very suitable for processing these precious metals.

Surface Area:

Whether it is the corrugated plate of the heat exchanger or the packing inside the tower, the purpose is to increase the contact area. Stamping molds are best at turning flat sheets into complex shapes with uneven surfaces, providing the maximum reaction/heat transfer area with the smallest volume.

Consistency and efficiency:

A distillation tower may require tens of thousands of bubble caps. Stamping production ensures that the size of each bubble cover is completely consistent, thereby ensuring the uniformity of airflow distribution inside the tower.

summary

In the chemical industry, metal stamping parts are usually hidden inside huge towers and pipelines.

They are the ripples on the heat exchanger, responsible for heat transfer;

They are the bubble caps in the distillation tower, responsible for purification and separation;

They are scratches on the explosive disc, responsible for sacrificing themselves to protect the factory in times of crisis.

Stamping technology enables chemical equipment to efficiently utilize expensive corrosion-resistant materials and achieve complex physical and chemical processes.

Ventilation systems and metal stamping parts

Ventilation systems and metal stamping parts

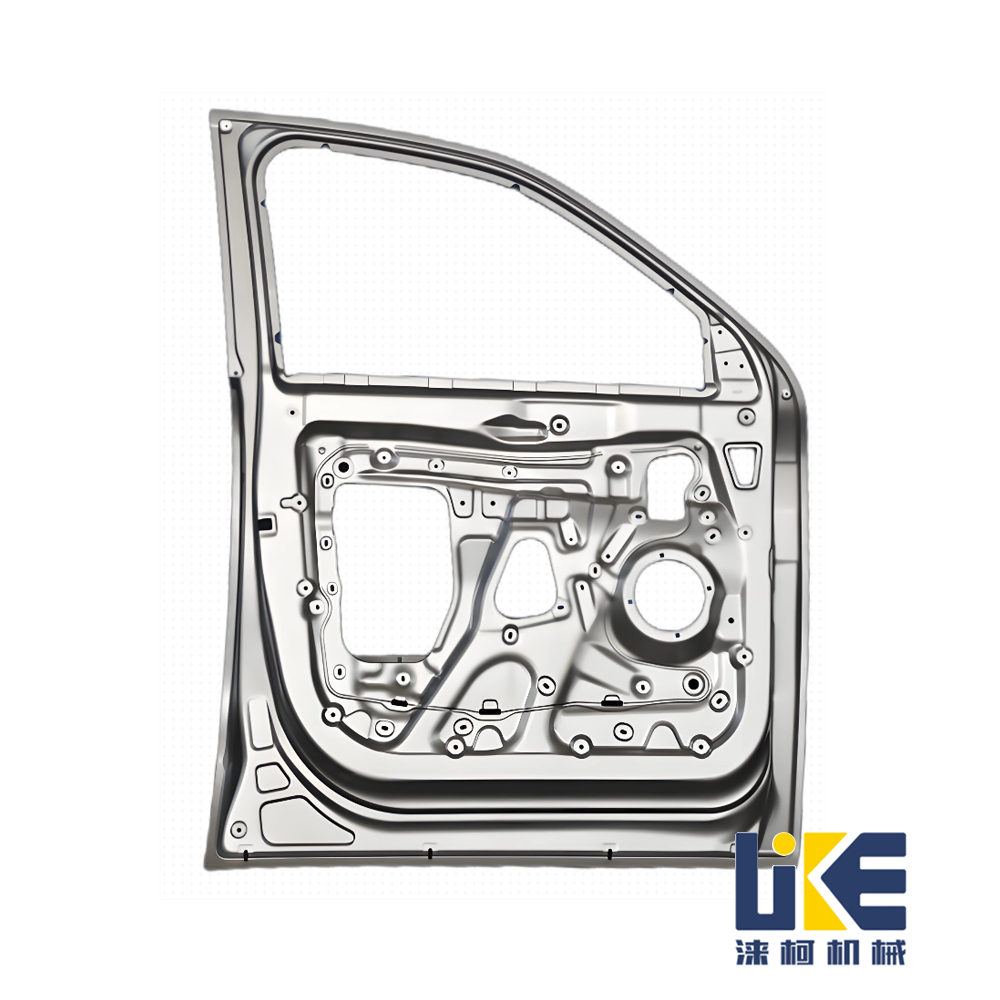

Automotive and metal stamping parts

Automotive and metal stamping parts

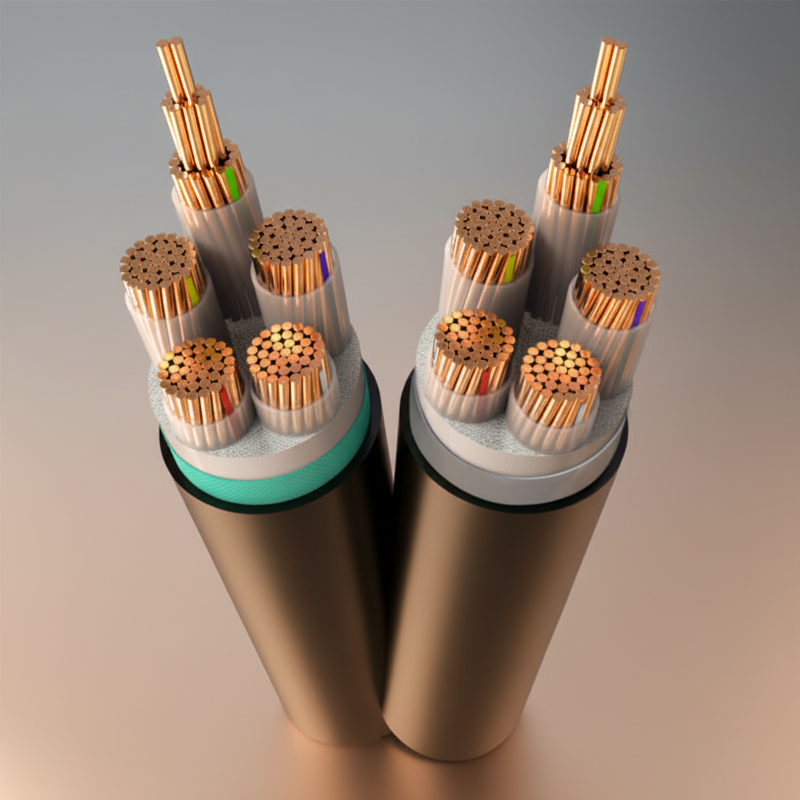

Cables and metal stamping parts

Cables and metal stamping parts

Numerical control equipment and metal stamping parts

Numerical control equipment and metal stamping parts